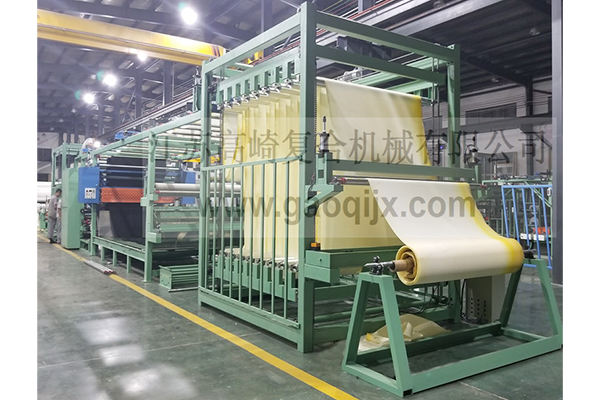

GQ-2100C type automatic three-in-one flame laminating machine (for clothing industry only)

Function principle:

The flame laminating machine is used to transform thermoplastic materials (such as sponges made of polyester, polyether, polyethylene other adhesive films textiles, PVC films, artificial leather, non-woven fabrics other materials) through Rapid flame burning compounded into 2 3 layer products. The bonding principle is that the linear gas burner quickly burns melts the sponge. The sponge produces a viscous film. The sponge, the upper fabric the interlining between the rollers will stick together when passing through the glue gap. The fire mouth can use imported domestic brands.

Main specifications:

1. Flame composite width: 1900mm

2. Combustion gas: petroleum liquefied gas, natural gas

3.Burning capacity: 2.5-3.5m3 / min (mixed gas)

4. Design speed: 10-60m / min

5. Transmission control power distribution capacity: 20KVA

6. Mechanical dimensions (LxWxH): 22000x3000x4200mm

The main advantages of the machine:

1. The production line can be controlled by a servo system, the transmission runs without noise, synchronization is accurate, the energy consumption is low.

2. Intelligent operating system, PLC touch screen control. To achieve simple operation, effective energy saving, intelligent data control, greatly reduce the labor intensity, can effectively ensure product quality, affected by human experience. According to needs, the working speed can be controlled on the touch screen, stepless speed regulation; the pressure roller gap can be adjusted according to different materials, different air gas mixing ratios can be set; different tensions can be set according to different materials to avoid product tension. Unevenness, tendency, etc.

3. Constant tension cloth storage rack mechanism: This machine adopts self-constant tension cloth storage principle control, which can effectively control the tension of the finished product after compounding, eliminating the curling fastness of conventional machines. At the same time, the tension can be adjusted automatically according to different product properties.

4. The raw materials are automatically corrected before being compounded, the width is automatically flattened. Automatic material return storage in advance, no downtime during roll change during production, high product quality stability.

5. According to the need to increase the gas constant pressure mechanism gasification furnace, with the seasonal climate change, the use of liquefied gas in winter gasification constant pressure, so that the fire uniformity stability of the fire.

6. According to the different materials made, the matching control system can be added, mainly for the uneven edges of special fabrics. According to different fabrics, you can choose to use the centering device.