In what fields are hot melt adhesive laminating machines used?

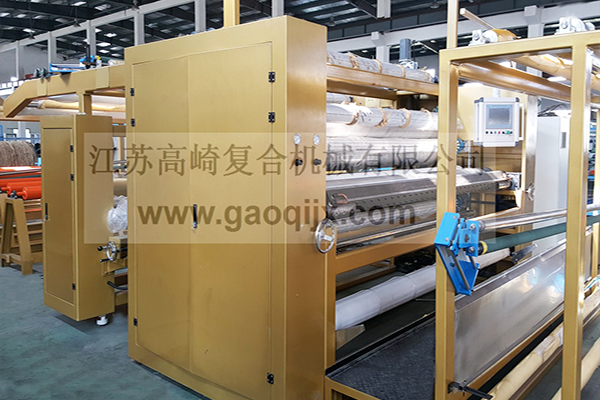

The hot-melt adhesive laminating machine uses an adhesive to bond two more layers of materials together. Commonly used film cloth glass cloth. It can be combined with paper, film, sponge, cloth, etc. Here is more information about MFP. Generally speaking, the compound machine refers to a kind of compound equipment for home textiles, clothing, furniture, automobile interiors other related industries. The hot melt adhesive laminating machine is mainly used for the composite production process of more than two layers of various fabrics, leather, film, paper, sponge so on. Specifically, it can be divided into cemented composite materials non-glued composite materials. The glued composite material can be divided into hydrogel, polyurethane oil glue, hot melt glue so on. Non-glued composite technology is mainly the direct thermal compression bonding flame burning bonding between materials. Currently, national standards for multi-function peripherals have been implemented.

Hot melt adhesive laminating machine is only widely used in packaging industry, but also often used in some public equipment production lines. Because some cables optical cables need to be used in wind, sun corrosive environments for many years, they need good waterproof, moisture-proof corrosion-resistant properties to ensure the performance design life of the cables optical cables.

During the operation of the hot melt adhesive laminating machine, the wear part of the transmission part is relatively serious, sometimes the shaft head of the dryer is worn, the other is the wear of the bearing chamber of the paper roll. Generally speaking, surfacing, thermal spraying, brush plating other methods are used to repair.

If the hot-melt adhesive compounding machine wears seriously, Gaoqi recommends that users consider replacing new parts doing routine maintenance of the machine to reduce machine wear.