GQ-JDZX-013 type large roll pile glue point compound machine

Alias: glue point transfer laminating machine, oil glue laminating machine, PU glue laminating machine, PU oil glue laminating machine, seamless wall covering laminating machine, large glue dot laminating machine, water-resistant laminating laminating machine, yellow glue laminating machine, etc.

Use:

Mainly used for apparel fabrics, non-down pile, fleece, plush, non-woven fabrics, terry cloth, cotton cloth, denim, TC cloth, lace cloth, leather, sponge, woven cloth, PU leather, PVC leather other materials Compound. It is widely used in industries such as clothing jackets, winter clothes, thermal underwear, urine pads, car interiors, shoes hats, bags, decoration, home textiles, etc.

Features:

1. The whole machine is upgraded with the functions of automatic deviation correction, automatic stripping, automatic centering, automatic opening, automatic blowing of waste materials, etc. The composite material has the advantages of even glue coating, smooth composite, no tensile deformation, no foam, no wrinkle, softness, good air permeability, neat winding so on.

2. There are many varieties of composite materials, especially suitable for the coating compounding of fabrics fabrics, fabrics double-sided four-sided elastic knitted fabrics, non-woven fabrics leather, sponges flannel, sponges leather, etc .;

3. The appropriate configuration can be selected according to different materials for winding unwinding;

4. According to the characteristics of different materials, some devices can be added removed;

5. It is suitable for the compounding of water-soluble solvent-based glue coating to realize the multi-function of one machine.

6. The amount style of glue can be adjusted according to the material actual needs.

7. The drum can be heated by electricity, steam thermal oil.

8. The width of the roller surface of the machine can be specified according to the width of the actual material.

9. The whole system can be controlled by intelligent PLC program touch screen mechanical type.

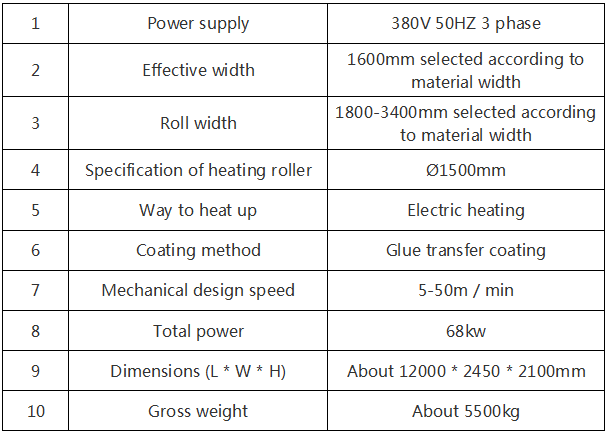

The main technical parameters:

用途:

主要用于服装面料、不倒绒、摇粒绒、长毛绒、无纺布、毛巾布、棉布、牛仔布、TC布、蕾丝布、皮革、海绵、机织布、PU革、PVC革等材料之间的复合。广泛适用于服装冲锋衣、防寒服、保暖内衣、隔尿垫、汽车内饰、鞋帽、箱包、装饰、家纺等行业。

特点:

1、整机在常规的胶点复合机的基础上升级了自动纠偏、自动剥边、自动对中、自动开幅、自动吹废料边等功能。使复合的材料更具有涂胶均匀、复合平整、无拉伸变形、不起泡、不起皱、柔软、透气性佳、收卷整齐等优点。

2、复合材料品种多,尤其适用于面料与面料、面料与双面或四面弹力型针织布、无纺布与皮革、海绵与绒布、海绵与皮革等材料的涂布复合;

3、收、放卷可根据不同的材料,来选择适合的配置;

4、根据不同材料的特性,可增减部分装置;

5、适用于水溶性和溶剂型胶涂布复合,实现一机多用的功能。

6、涂胶量与涂胶样式可根据材料及实际需要调整。

7、滚筒加热可采用电、蒸气或导热油的方式来进行加热。

8、机器辊面幅宽可根据实际材料的幅宽来特定。

9、整机系统可采用智能PLC程序触摸屏或机械式来操作控制。

主要技术参数: