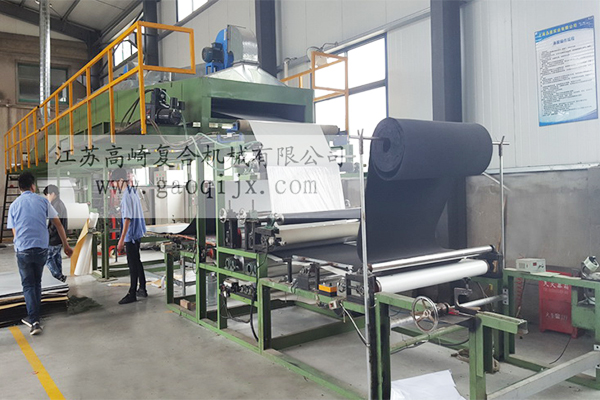

GQ-BGJ-008A foam self-adhesive laminating machine

Purpose scope:

1. This machine is suitable for coating oil-based water-based pressure-sensitive adhesives such as release paper, cotton paper other substrates after drying combining with sponge, PE, EVA, cloth other web-shaped roll-shaped materials.

2. Mainly used raw materials:

1). Base material: release paper (silicone paper), cotton paper, film (BOPP, CPP), etc.

2), glue: oily water-based pressure-sensitive adhesive. Solvent based.

Technical characteristics:

1. Tension control system: the whole machine adopts magnetic powder tension control system for winding unwinding.

2. There are one set of EPC gas-liquid automatic correction device for each of unwinding frame, rewinding frame exit gate (total three sets)

3. Oven safety system: when the oven temperature reaches the set temperature, the heating is automatically stopped, when it is lower than the set temperature, the heating is automatically heated, the interlock circuit of the exhaust system the heating system is set to improve the production. Low energy consumption, uniform heat, intelligent digital display PID thyristor temperature control system, high temperature control accuracy.

The main technical parameters of the machine:

1. Effective coating compound width: 1500mm (coating roller, doctor blade, compound roller width 1800 mm)

2. Design mechanical speed: 1-35m / min

3. Coating compound speed: 5-30m / min

4. Total motor power: about 25KW

5. Electric heating power: about 100KW (full load power)

6. Uniformity of coating: plus minus 0.005mm (dry glue)

7. Controllable glue coating thickness: 0.01mm (dry glue)

8. Dry heating method: electric heating hot air circulation

9. Coating method: comma scraper rod After heat treatment hard chromium plating on the surface, fine grinding process is resistant. Good friction performance, wear resistance scraping performance.

10. Temperature control method: up to 120 degrees, plus minus 3 ℃, total length of 12m (optional), tunnel type tunnel arch structure.

11. The amount of glue: the amount of wet glue is 20-120g per square meter.

12. Unwinding diameter: φ1000mm (paper core 3 ")

13. Rewinding diameter: within φ1000mm (paper core 3 ")

14. The offset of the winding end face is greater than: ± 2mm.

15. Temperature control accuracy of the drying tunnel: during normal production, the temperature of the hot air in the oven is higher than 100 ℃, the accuracy is ± 3 ℃. The four-stage temperature is independently controlled can be set adjusted.

16. Power supply: 380V ± 10%, 50HZ, three-phase five-wire.

17. Total installed power: about 100kw. (The power consumption during normal production is about 40kw) For reference only.

18. Overall dimensions (length × width × height): about 18000mm × 3000mm × 4550mm.