GQ-PUR2000 type urine pad material compound machine (PUR hot melt adhesive compound machine)

Structure of compound machine for urine pad material:

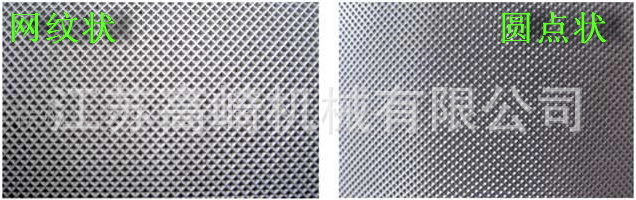

The equipment control of the compound machine for urine pad material adopts programmable PLC design man-machine interface control, humanized operation, easy maintenance, tension-free discharge device, heating circulation system, which is convenient to control the temperature rise stability of the glue fit the material the finished product can adopt the center winding surface selection method according to the needs. The gluing method is divided into two options: dot-like net-like coating.

Use of compound machine for urine pad material:

The machine uses solvent-free environmentally friendly PUR hot melt adhesive, which can fit the composite materials required by various markets such as cloth + film + cloth, cloth + film, cloth + cloth so on. Widely used in clothing, home textiles, decoration, shoes hats, automotive interiors, abrasives, medical other industries. The composite product has the characteristics of environmental protection, good adhesion flexibility, high low temperature resistance, easily affected by temperature after moisture reaction, long-lasting elasticity, wear resistance, oil resistance, aging resistance. In addition, PUR has excellent matte performance, low precipitation neutral color characteristics, can be applied to medical products that require repeated disinfection. The finished product compounded with the PUR hot melt adhesive laminator has a lower loss rate a higher washing fastness. The PUR hot melt adhesive laminating machine can completely replace the traditional solvent-based laminating equipment. The production process does use flammable, explosive toxic solvent-based glue. The factory has no hidden safety hazards meets the safety requirements of the national safety supervision department. It is far away the harm of the solvent to the body, there is no solvent residue in the composite product, which fully meets the export environmental protection standards has great social benefits.

Features of urine pad material compound machine:

1. The PUR hot melt adhesive used does contain solvents is an ideal green environmentally friendly solvent-free glue;

2. There are no residual solvents in the products, no pollution emissions in production, energy saving, small footprint;

3. The wet-solid reaction in the process of compounding is irreversible, the bonding is firm the washing fastness is good;

4. PUR hot melt adhesive does contain water solvent, no drying is required, the compounding speed is fast;

5. Strong viscosity, less glue consumption cost saving;

6. Full linkage control of compounding process, no stretching of the base material, light soft, good hand feeling;

7. The heat source is oil-conducting heat, heating is fast, the heat is uniform, energy saving;

8. The melting system is independent, the melting speed is sufficient;

9. Dot-shaped reticulated glue, good air permeability strong three-dimensional sense;

10. The humanized design of the machine saves the operator;

11. It has a small amount of diversified production design, saves costs, a digital control system makes the operability better.

12. The web (circle) dot roller pattern is divided into various options, the size depth of the pattern can be customized according to different requirements of customers.

Technical parameters of the compound machine for urine pad material:

1. Working cloth width: 1800 mm (selected according to material width)

2. Width of mechanical roller: 2000mm (selected according to material width)

3. Design line speed: 5 ~ 45 m / min

4. Mechanical dimensions (length * width * height): 8300 × 3300 × 2200 mm

5. Heating power of heat conduction oil: 24KW 12KW adjustable thermal oil circulation 180 ℃ (MAX)

6. Total mechanical power: about 45KW

7. Power supply: 380V 50Hz three-phase

8. Total weight of equipment: about 7500KG