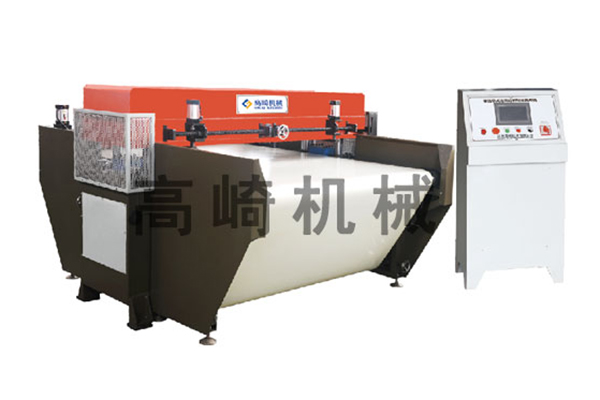

XCLL3-600 Conveyor Belt Continuous Feeding Precision Cutting Machine

Purpose Characteristics:

1. This machine is suitable for continuous large-scale blanking operations of carpets, leather, rubber, cloth other non-metallic materials with molding knives in large factories.

2. The conveying part is controlled by PLC. The servo motor drives the material to be input one side of the machine. After die cutting, it is output the other side to ensure accurate feeding stable operation; the feeding length can be easily adjusted through the touch screen.

3. The main machine adopts four-column guide, double crank balance, four-column deadlock fine adjustment mechanism, hydraulic system control to ensure the die cutting speed accuracy of the machine. The sliding connection part adopts a central oil supply automatic lubrication device to reduce wear.

4. The input output of materials are conveyed on the conveyor belt, the die cutting punching of the materials are also automatically completed on the conveyor belt.

5. The use of photoelectric pneumatic correction device to ensure the accuracy of the conveyor belt operating position.

6. Safety light curtains are installed at the inlet outlet of the cutting area of the machine to ensure the personal safety of the operator.

7. Pneumatic clamping device is used to fix the die, which is convenient quick to change the die.

8. Special specifications can be customized.