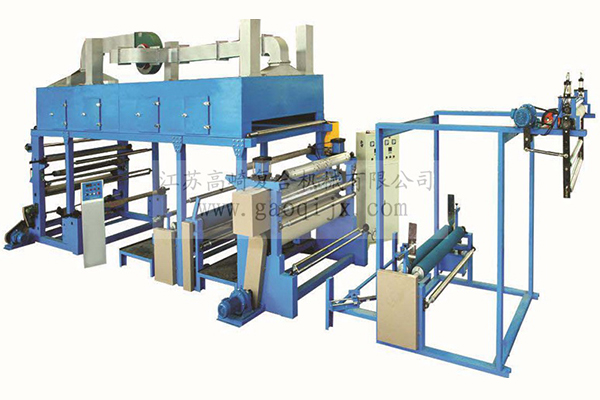

GQ-1800 Thermal Transfer Film Hot Stamping Machine

Thermal transfer film bronzing machine • Use:

It is mainly applied to the surface local hot stamping pressing of fabrics such as polyester, nylon, acrylic, polypropylene other blended knitted fabrics, woven fabrics, cotton cloth silk fabrics. Widely used in clothing, home textiles other industries.

Thermal transfer film bronzing machine • Features:

1. Based on the original paper gold presses, our company has designed a new type of process bronzing equipment with reference to the Korean bronzing equipment, combined with the actual needs of users.

2. The hot stamping machine has clear hot stamping, easy operation, convenient, intuitive friendly, the mechanical structure is more reasonable.

3. The front rear transmission of the whole machine is designed to operate on the top of the head, which avoids the inconvenience of transporting materials on the ground causes the inconvenience of transporting materials. It rationally uses saves space.

4. The gold feeding inlet does require manual feeding. Through automatic edge spreading, the flattening function can achieve the effect of bronzing compound, at the same time achieve the purpose of saving manpower.

Thermal transfer film hot stamping machine • Main technical parameters:

1. Based on the original paper gold presses, our company has designed a new type of process bronzing equipment with reference to the Korean bronzing equipment, combined with the actual needs of users.

2. The hot stamping machine has clear hot stamping, easy operation, convenient, intuitive friendly, the mechanical structure is more reasonable.

3. The gold feeding inlet does require manual feeding. Through automatic edge spreading, the flattening function can achieve the effect of bronzing compound, at the same time achieve the purpose of saving manpower.

Sofa coating hot stamping machine • Main technical parameters:

1. Equipment width: 1800mm (width can reach 3000mm)

2. Operating car type: left hand right hand

3. Running cloth speed: 5-35m / min.

4. Rubber roller: Imported silicone rubber (composite place) nitrile rubber (glue place) respectively

5. Heating roller: 45 # steel hard chrome plated (mirror surface) sprayed Teflon surface treatment, intelligent temperature controller

6. Transmission: The gear transmission is the main the belt is auxiliary. All the inverters are used to control the synchronization of various actions.

7. Wallboard: welded welded by steel plates.

8. Oven: hot air circulation oven, slit nozzle, uniform heating.

9.Temperature control exhaust: multiple drying channels with independent temperature waste control

10. Pressing method: using oil pressure.

11. Power of the whole machine: about 100KW (in the form of electric heating), it can also be heated in the form of thermal oil steam

12. The operation interface adopts PLC touch screen man-machine operation interface.