Sand release special solvent glue compound machine (with storage rack)

Commodity details

Performance characteristics

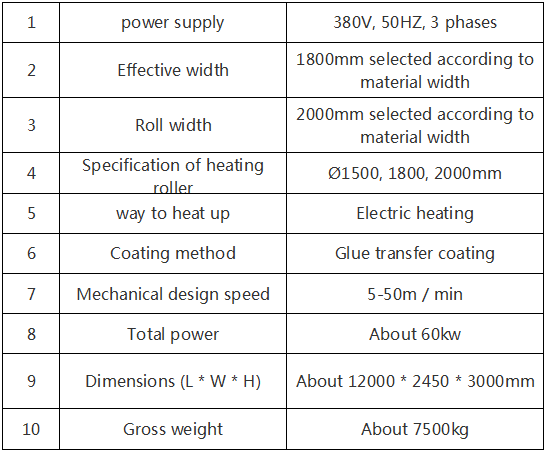

technical parameter

GQ-001F Solvent glue laminating machine for sand release (with automatic storage rack) is mainly used for laminating non-elastic cloth

Alias: one-end cloth feed laminating machine, sand release laminating machine, PU oil glue laminating machine, glue point transfer laminating machine, oil glue laminating machine, automatic storage compound machine

Use:

Mainly used for apparel fabrics, non-down pile, fleece, plush, non-woven fabrics, terry cloth, cotton cloth, denim, TC cloth, lace cloth, leather, sponge, woven cloth, PU leather, PVC leather other materials Compound. It is widely used in industries such as clothing jackets, winter clothes, thermal underwear, urine pads, car interiors, shoes hats, sofas, bags, decoration, home textiles.

Features:

1. On the basis of the conventional glue compound machine, the whole machine is upgraded with functions such as automatic deviation correction, automatic centering, automatic edge stripping, automatic opening width, automatic waste blowing edge. The composite material has the advantages of even glue coating, smooth composite, no tensile deformation, no foam, no wrinkle, softness, good air permeability, neat winding so on.

2. There are many varieties of composite materials, especially suitable for the coating compounding of fabrics fabrics, fabrics double-sided four-sided elastic knitted fabrics, non-woven fabrics leather, sponges flannel, sponges leather, etc .;

3. The appropriate configuration can be selected according to different materials for winding unwinding;

4. According to the characteristics of different materials, some devices can be added removed;

5. It is suitable for the compounding of water-soluble solvent-based glue coating to realize the multi-function of one machine.

6. The amount style of glue can be adjusted according to the material actual needs.

7. The drum can be heated by electricity, steam thermal oil.

8. The width of the machine roller surface can be specified according to the large width of the actual material.

9. The whole system can be controlled by intelligent PLC program touch screen mechanical type.

The main technical parameters: