Hot melt adhesive spraying compound machine

Commodity details

Performance characteristics

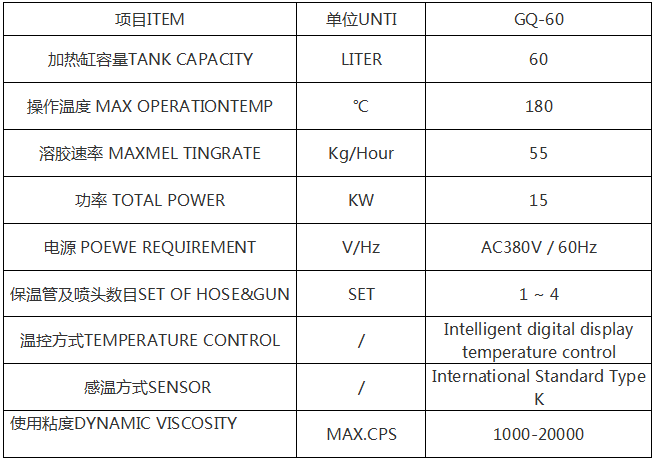

technical parameter

GQ-1800 non-woven fabric hot melt spraying compound machine

1. 24-hour unattended management function, dependent on hardware, various automatic control events time can be set on the touch screen;

2. Reasonable protection measures, various exception handling alarms under fully automatic operation state to ensure equipment safety;

3. Convenient operation, concise, easy to learn;

4. Support joint configuration control of frequency converter, PLC module computer touch screen;

5. The temperature sensor signal supports K / PT100 / NI120, high-precision signal acquisition;

6. The gear adopts imported pumps-the glue is stable, the precision metering pump is used, the buffer connector is used, the glue is stable reliable;

7. The melter can be operated by color touch screen display, the two main screen styles can be switched online;

8. 1 screen supports 2/4/6 hose system, online selection switch system configuration, good interchangeability;

9. Multi-machine networking can be supported according to requirements, on-site operation + remote networking operation, storage management function;

10. 3000VDC input signal isolation, high anti-interference performance, to ensure reliable operation of the module;

11. The TVS PTC component protection modules operate are safe to plug unplug;

12. PID online self-tuning stable temperature control, temperature control over-dispatch online optional.

Application range:

Packaging, automotive interior industry, printing industry, filtration equipment consumables, medical health, home furnishing, building materials, decoration other industries.

The main application is applied to: non-woven fabric, film, fabric, paper roll, leather, foam other materials after spraying hot melt adhesive for compounding. The amount of glue sprayed can be set according to user needs.

Advantages: good air permeability, less glue, no odor, environmental protection.

Characteristic:

1. The temperature is controlled by an intelligent digital display temperature control instrument, the user-friendly design of the operation panel, easy operation.

2. Large internal space, easy heat dissipation good thermal insulation effect.

3. Frame-type fuselage structure openable control cabinet door design, simple fast installation maintenance.

4. Equipped with electrical components of well-known foreign brands, controlled by independent temperature control table.

5. High-precision imported gear pump, stable output of glue volume pressure, control glue volume improve production efficiency.

6. High-strength integrated casting into the melt, radiating heating the manifold, increasing the heat transfer area, increasing the melt rate.

7. Progressive pre-heating melting tank design, first-in-first-in melting, coated with imported Teflon anti-stick coating, low energy consumption, reduce carbonization, reduce clogging, maintain the quality of glue.

8. The precision filter device removes impurities, keeps the glue flowing smoothly, prevents the nozzle clogging.

9. Equipped with high-precision return valve to keep the glue out stable.